Do you have any questions about etching technology and laser technology?

You can find answers to the most frequently asked questions on this page.

Material selection and heat treatment play a key role with regard to the later graining result. Even at the material procurement stage it is important to

ensure that only steels are used that are suitable for graining. All relevant

tool components (sliders, inserts, etc.) should be produced from the same

material to avoid possible risks to the grain quality and gloss level.

Suitable materials include:

| Code name | Material no. | Eschmann name |

| 40 CrMnNiMo 8-6-4 --- --- |

1.2738 EST Special alloy --- |

ES Aktuell 1000 ES Aktuell 1200 *) Standard for master pattern |

| 40 CrMnMo 7 --- |

1.2311 EST Special alloy |

ES Aktuell ES Multiform SL |

| X37 CrMoV 5-1 --- |

1.2343 ESU *) limited Special alloy *) limited |

ES Maximum 500 ES Primus SL |

Use ESR (electroslag remelting) quality material in hot work steels. There may be a difference in the grain quality and/or gloss level (depending on the thermal conductivity, amongst other things) in comparison to conventionally hardened and tempered plastic mould steels due to case hardening and the alloy!

*) see “What is meant by gloss level?”

Apart from alloyed steels, the most common non-ferrous metals (e.g. copper, aluminium, brass or zinc) and non-alloyed steel can also be etched. However,

it is generally recommended to test the desired etching result in advance on

a trial plate. For some of these materials a rougher etching base and/or a completely deviating grain quality, amongst other things, may be produced

as a result of the chemical reaction of the acid with the base material.

Non-ferrous metals do not have 100 percent graining capability.

Hardened Edge

Porous

Edge

Welding should generally be carried out by a specialist company and the graining capability of the welded areas needs to be guaranteed. A key

factor in determining a structure's suitability for welding is that the weld

metal has the same structure as the base material in terms of composition, hardness and strength. Accordingly, the welding method, material and necessary heat treatment must be selected on the basis of their later

graining capability.

Welding requirements:

The minimum draft angles for the ejection of the full grain depth are indicated for each structure.

The following rule of thumb applies:

A maximum grain depth of 0.02 mm can be ejected for each 1° of conicity.

Plastic properties (e.g. flame-retardant design, glass-fibre reinforced, etc.), material shrinkage, wall thicknesses and tool design and contour (e.g. cooling, sprue, sliders, etc.) and production parameters in injection moulding operations can influence this value. For example, in areas with expected core shrinkage, three times the standard conicity value for the ejection of the full grain depth may be necessary.

The following should be taken into consideration for a tool design compatible with a moulded part:

Scuffing is a deformation of the plastic in the direction the item is ejected and is frequently referred to as "stress whitening". The causes for this may be wall thickness changes, high graining pressure, insufficient shrinkage of the item, material properties of the plastic used, etc. Although it is possible to optimise the scuffing over the grained surface by reducing the grain depth, this must be agreed in detail with the end user as this will change the grain impression.

Note:

The occurrence of scuffing cannot generally be excluded, even with adequate draft angles as well as reduced grain depth!

Free-form areas on the sliders and/or insert split lines are often not permitted for items in which the graining is in the main visual area. Loose tool parts are grained in the assembly in such cases, i.e. over partitions.

It is important to ensure the following:

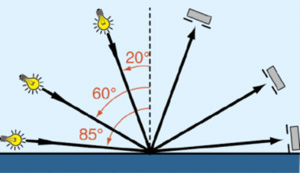

"Gloss is a visual perception that occurs when viewing surfaces. The perception of glossiness is more pronounced, the more directionally the light is reflected."

The light is not only reflected in the main direction of reflection but also reflected diffusely in other directions with rough – and thus etched – surfaces.

This reduces the reproduction accuracy of the surface: a reflected object is no longer depicted as a brilliant image, but as a blurred image. The more uniform the diffusion of light into the room, the lower the intensity of the directional component and the more matt the surface.

The gloss level is determined by: